What the Factors to Consider Before Upgrading the Control System

Contents

1) Site Survey – (Know How)

2) Documentation Input Step

a. Collect Existing Database Backup

b. Retrieve Existing DCS Control Function Narrative / P&ID/ Logic

Drawings/Logic Charts

c. Process Graphics snapshot/layout

3) Scope Identification Step

a. Revamp and new function development

4) HMI Layer Works

5) Project Execution Strategy

6) Time Synchronization

1. Site Survey – (Know How)

Know the existing system:

· Ask

whether the existing controller will remain, or be replaced.

· Are

there any ESD system in the project?

· What

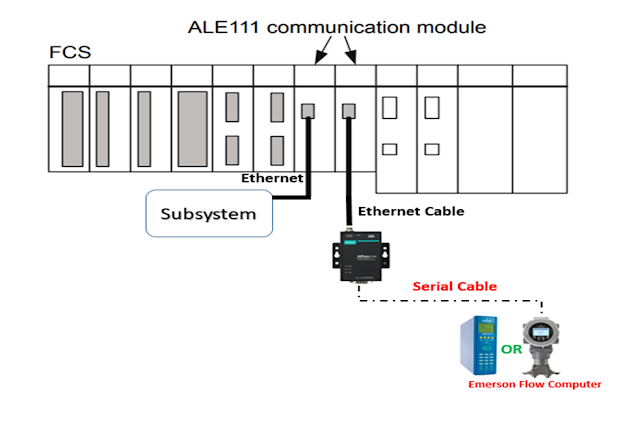

are the associated 3rd party packages interface with the DCS?

How points/IOs are have been mapped/integrated with the DCS?

· Are

there satellite instrument houses, the RTUs, if yes, get more information about

them.

· Are

there any paper data or electronic data of the existing system?

· Ask

the total count of IO and the number of each type (Analog I/O, Digital I/O).

2.

Documentation

Input Step

Collect Existing Database Backup

Check for the availability of backup files or

any relevant material from the existing control system. Discuss with the system

custodian generally the ICSS engineer from the maintenance team related to the

type of backup file available in the beginning. For example, in the case of

Yokogawa centum VP, the project engineer shall back up all relevant files

having the extensions BOX.EB, TAG.EB, CL, and DX file, etc. with text format.

These files need to be read in the Windows system afterward. It is necessary to

ensure the integrity of the database and it should include all applications.

Make sure that the integrity check and availability of all relevant application

files in the database have been confirmed before the FAT stage.

Retrieve Existing DCS Control Function Narrative / P&ID/ Logic Drawings/Logic Charts

· Collect all

logic drawings/files having the control function narratives applied within

these modules. Log the File revisions. Check the integrity and make sure the

latest revision has been retrieved. Take more attention/highlight any updated

control function in the system but it is not reflected in documents.

·

Pay special

attention to the complex loops.

·

Prepare a neat

and clear master file for all these configuration files.

Process Graphics snapshot/layout

Save all process graphics snapshots.

Coordinate with the ICSS engineer and focus on the special graphics or any

pop-up graphics having any customized function codes scripted within the

existing graphics. Note the layout of the graphics with care.

3. Scope Identification Step

Revamp and new function development

Try to get answers to the following questions:

·

What function

will be revamped during this migration project?

·

What new control

function is to be implemented in the new system.

·

Make sure the

scope is clear.

IO list master

·

Get the master

IO list

·

How to handle

the dummy IO for the existing system.

·

What can be

deleted and what is still to keep in the new system

4.

HMI

Layer Works

Graphics style /Hierarchy

Elaborate the change in graphics to the customer

or end user. It should include the graphics style, such as background color,

pipe color and thickness, equipment symbol etc.

Discuss with system custodian and acquire clear

understanding on the following modules:

·

Operation group

·

Control

group

·

Trend group

·

Report

assignment

·

Alarm philosophy

·

Operation

Keyboard assignment (if the propriety keyboard is being used; provided by the

control system OEM).

5. Project Execution Strategy

Project execution

Plan the project timeline and prepare the

strategy for actual onsite deployment during the best available window.

Normally that happens during the turnarounds so know the duration of

shutdown.

·

Know the graphic

conversion policy (redesign or conversion)

·

If conversion,

full or partially (identify target graphic)

·

Can we get a

backup of database of existing system.

·

Do we need

prepare FDS, and the approval process of it.

·

DCS engineering

·

Know the

scanning time of system.

·

Are there Batch

process in this project? If yes, how they manage recipe modification and

change.

·

Know whether

they use DOC3000 for modification or maintenance.

·

Do they fell

difficult to manage instrument asset, and what kind of issue resides in site.

Yokogawa PRM provides this function.

·

Are they facing

a risk of knowledge loss when senior DCS engineer retired. Yokogawa exapilot is

useful

·

Migration

·

Ask if it is

possible to make database (*.EB, *.CL) updated before they hand it to us for

analysis

·

What kind of

database can be provided?

·

Does they want

to keep current graphic design or build it from scratch.

·

Know the

functions in AM.

·

In case that

existing annunciators shall be retained, try to get all alarm information

related to existing annunciator.

·

System structure

of existing system, electronic data or paper files.

·

Migration story

provided by Honeywell for existing system, if possible.

6. Time Synchronization

Time synchronization Scheme

What scheme is being used for time

synchronization of all workstations and controllers on the control network?

Either the Network Time Protocol (NTP) is being used or any physical

workstation is being defined as the Master Time Server node through the

Physical Network Properties provided in the system.

We need to discuss the scheme for time

synchronization.

Generally, the control

system providers provide a precise system time for their customers using

the Global Positioning System(GPS) network time server having a

specific IP address on the control network.

7. Miscellaneous

Is any smart instrument with DE protocol used?

Any DE protocol/STIIM instrument used or not in the existing system. Online modification is not permitted without PRM

Do not miss some special functions that are only

applied in the existing system.

2 Comments

Really informative

ReplyDeleteThanks for the appreciation. Means a lot.

Delete