Third-Party Integration with DCS - Example

Content

- What is a third-party system in the control system?

- What are the Interfacing Protocols?

- SCADA Interface – DCS Server is acting as the middleman

- Direct interface with DCS Controller

- Example of third party system interface:

- 1. MPFM

- 2. Compressors

What is a third-party system?

Any unit, equipment, or

electronic device that has several process or operational parameters and

its integration with the control system is not like the conventional Input/output thereby requiring a separate

communication protocol shall be coined as a 3rd party system. For

example, in an oil and gas processing facility, the DCS system is there for

operation and control of the processing operations, while other units like the power

generation system act as a separate operational unit. The operational status

of power generation including the unit’s run status, alarms, electrical

parameters, voltage, current, and power ratings are relayed to the central control

system through a separate mechanism. This power generation system shall have

its own PLC-based control system which is responsible for the operation, control, and safety of the power generation system. However, for the centralized

monitoring few key critical parameters like the status of operational units,

emergency shutdown status, etc shall be sent to the central DCS. This

interfacing shall be unlike the typical IO. To integrate this system,

separate hardware, software, and communication mediums shall be required. In this

write-up, we shall discuss this in detail. As an example, two test

cases shall also be presented as it follows. Interfacing MPFM with DCS or any

gas compressor station with DCS shall be presented as an example to further

understand this 3rd party integration with DCS.

Firstly

the interfacing protocols shall be discussed which is largely relevant to the

DCS system end. Secondly the aforementioned stated examples shall be elaborated

further to simplify the integration concept.

Interfacing Protocols

We shall discuss two approaches here. The first approach is the SCADA interface using the DCS server as the middle man and the second approach is a direct interface with the DCS controller without any server as the middle man.

1. SCADA Interface – DCS Server is acting as the

middleman

Example: Honeywell – Quick Builder

SCADA points in Honeywell is defined using the Quick Builder. From Configuration

Studio, open Quick Builder. It is the tool to create and maintain a

configuration database that comprises of Channels, Controllers, and points.

Generally, a parameter is defined as a Point

and grouped under the Controller. The group of

controllers is then clubbed under the Channel.

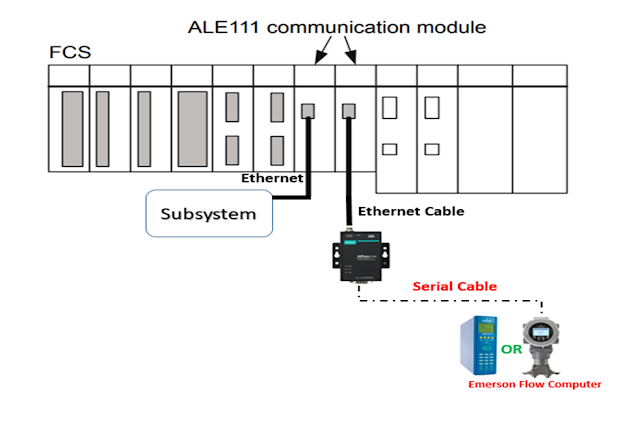

2. Direct interface with DCS Controller

Example 1: Yokogawa – ALE Card Model ALE111, Ethernet Communication Module

ALE card is used for the configuration of SCADA points in Yokogawa DCS. This module is used to perform Ethernet communication with subsystems.

Example 2: DeltaV – Serial Card

It must be kept in mind that a

process controller must not be loaded with communications duties in addition to

normal processing, hence central processing unit loading must be done

carefully. This could necessitate a dedicated communications controller to

handle third-party data.

Example:

1. MPFM

Parameters;

|

|

MASS FLOW |

MASS TOTALIZER |

VOLUME FLOW |

DENSITY |

|

OIL |

KG/S |

KG/S |

SM3/H |

KG/M3 |

|

WATER |

|

|

|

|

|

GAS |

|

|

|

|

Some other parameters

- Common alarm

- Gas volume fraction

- Gas-liquid ratio

- Basic sediment water

- Gas Oil Ratio

- Venturi DP mbar

- Flowing Temperature Deg C

- Flowing Pressure Barg

- Mass Totalizers for Oil, Water, Gas in Kg

- Mass Totalizers for Oil Water Gas in Sm3

2. Compressors

Gas engine-driven compressors or diesel engine-driven compressors are widely used in natural gas processing facilities in the oil and gas industry. These compressors are used at the final export line for injecting the processed natural gas into the gas network or they are also deployed at the front end for increasing pressure of mixed/raw hydrocarbon flowing from reservoirs to inlet separators or slug catchers of hydrocarbon processing facility. There are hundreds of parameters related to plant operation and engine/compressor operation. Usually, plant operation-related parameters are directly connected to the DCS through conventional hardwired 4 to 20 mA schemes like pressure, temperature, and flow transmitters; generally, these instrumentations are called off-skid instruments. While the on-skid parameters associated with the engine compressor are connected with the on-skid PLC.

- Bearing temperature

- Engine Lube oil pressure

- Engine Lube oil temperature

- Compressor lube oil pressure

- Cylinder exhaust temperature

- Engine speed/rpm

3 Comments

Really helpful for understanding these topic

ReplyDeleteVery nice blog

ReplyDeleteI am glad that you liked it.

Delete