What are the communication protocols for SCADA?

SCADA stands for Supervisory Control And Data Acquisition.

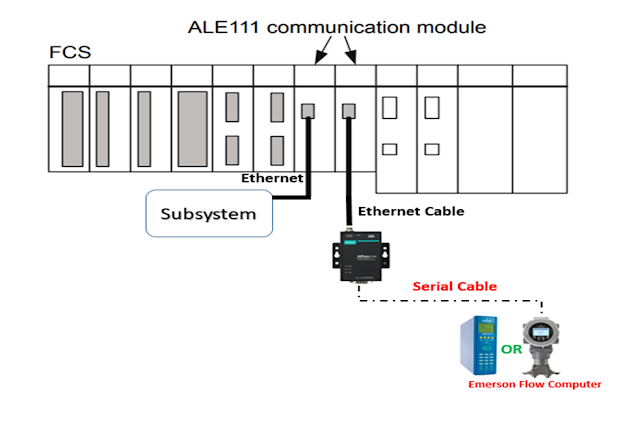

Here we shall discuss the commonly used communication protocols for transfer to data from field devices to the central control room panel. In central control room this data is required for centralized monitoring and control of various nature of operation. For example in case of multiphase flow meter; the flow computer installed on multiphase flow computer provides complete data related to wellpad/wellhead flow profile which is then display at distantly located centralized control room station through SCADA.

- DNP-3

- Modbus

- Ethernet IP

- OPC

|

| General scheme for data flow from field to control system |

IEC-104 is largely used for communication in the power sector. In some cases you will also find the DNP-3 protocol being utilized in the power sector as well.

DNP-3

It is an industrial protocol that communicates field devices to the SCADA server. Field device generally include PLC/RTU or any data logger. SCADA server is generally provided by Honeywell, ABB, Rockwell or any other renowned brandk. DNP-3 is widely used in water industry as well as in the oil and gas industry. It provides time based data event. It has different alarm classes and event classes which helps in filtering data as per user requirement. Remote configuration of SCADA server is also possible with this protocol. It also offers many security features that ensure the client has very safe and secure operation technology (OT) network.

This protocol is known for its timestamp functionality, buffered event, and the security. It is designed for the long distance communication.

MODBUS

Modbus TCP/IP or Modbus serial is mainly used in the oil and gas sector across the globe.

This protocol is very old protocol created by Modicon back in 1970s, initially used as a propriety protocol for Rockwell PLCs. Modbus is very simple and efficient to use.

ETHERNET IP

OPC

OPC and OPC UA has gained popularity with the advancements in the automation industry. This protocol not only has the timestamp, alarms, events, and information but also it can be integrated to data historian. This brings alot of advantages for the clients as they don't have to do the protocol conversion between the field device, SCADA and the data historian. This brings much efficiency to the system integration, and also enhances the integrity of the data as well.

0 Comments