What are the Design Basis Guidelines for an Oil & Gas Industrial Instrumentation Project

General Requirements

The instrumentation must

adhere to established engineering practices and procedures outlined in this

specification and any other pertinent specifications for the project.

Instruments must undergo review by the Company to ensure compatibility with the Project Specification in terms of design, operability, and maintenance. Only instruments with proven design must be used, emphasizing reliability and appropriate materials.

Process fluids, steam,

or water must not be directly measured in local control panels or the central

control room; instead, measured variables must be transmitted electronically.

For remote indication

and/or control, signals must be converted to electrical signals (4-20mA) at

24VDC for transmission; no pneumatic signals should be sent to the central

control room.

Unconventional or unique

instruments or instrumentation design practices should be avoided;

standardization should be maintained wherever possible.

All measuring

instruments should have over-range protection whenever feasible.

Instruments must be made

of high-quality materials and manufactured under recognized quality control

programs.

Instrumentation should be installed on skid modules whenever possible, including all necessary connections and wiring to junction boxes.

Instruments should be

pre-calibrated and function tested in the Vendor’s shop prior to export

packing; for PLC-controlled units, Factory Acceptance Testing must be

conducted, with the option for the Purchaser to witness at their own cost.

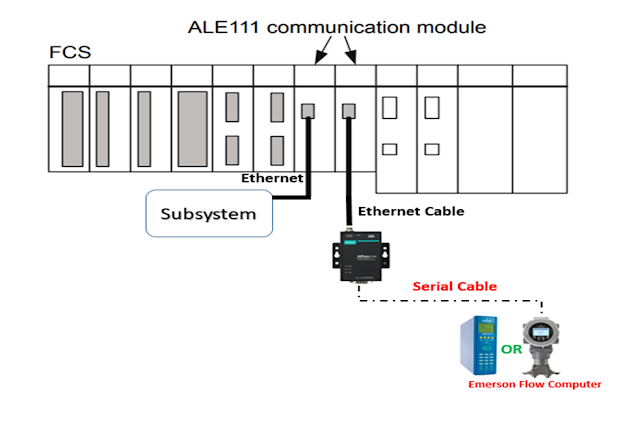

Preferably, PLCs should

be used in Vendor packages involving sequence and process control,

communicating with DCS and ESD systems via specified protocols.

Vendor-provided drawings

must accurately depict field instrumentation installation details, including a

Bill of Material, with each drawing representing typical installation details

for multiple tagged instruments.

All tube fittings must

be 316SS Swagelok or equivalent, with other bulk materials accurately described

in terms of material, size, pressure, and temperature ratings.

Flow and pressure

transmitters should be line-mounted whenever possible to minimize errors, but

accessibility must be ensured.

Instruments in vapor or

gas service should be mounted above the sensing point, while those in liquid

service should be mounted below; exceptions apply for pressure gauges.

Canopies must not be

provided for local control panels; sun shades must be provided for Analyzers

and RTU Panels.

When indoors, all vent

ports of instruments and regulators using instrument gas must be vented outside

the building.

Instruments, associated

components, and connections must be installed according to approved

installation drawings.

Local control pneumatic

instruments should generally have output signals of 3 to 15 psi; electro-pneumatic

devices should receive 4-20mA signals from the PLC system.

Instrumentation and

control systems should be designed for simplicity, reliability, and minimal

maintenance.

Field-mounted instrument housings and exposed parts must be weatherproof and explosion-proof where necessary.

All proposed plastic

components, along with toxicity and fire hazard details, must be specified in

the Vendor’s quotation.

The project piping

specification must determine process connection sizes, types, and ratings for

various instruments.

Special attention must

be given to material selection for instruments when dealing with highly

corrosive fluids or sour service.

All instrumentation and

control systems should be designed to operate in a fail-safe mode.

Instruments and

components must be carefully selected to suit internal fluid conditions and

environmental factors

Packaged supplies

must ensure instruments or their connections do not extend beyond the skid

limits.

Instrument parts

must withstand the corrosive properties of the process fluid they are exposed

to.

Seals and purges should

be employed as needed to guarantee reliable instrument performance.

Instruments must undergo

review by the Company to ensure compatibility with the Project Specification in

terms of design, operability, and maintenance. Only instruments with proven

design must be used, emphasizing reliability and appropriate materials.

Process fluids, steam,

or water must not be directly measured in local control panels or the central

control room; instead, measured variables must be transmitted electronically.

For remote indication

and/or control, signals must be converted to electrical signals (4-20mA) at

24VDC for transmission; no pneumatic signals should be sent to the central control

room.

Unconventional or unique instruments or instrumentation design practices should be avoided; standardization should be maintained wherever possible.

All measuring

instruments should have over-range protection whenever feasible.

Instruments must be made

of high-quality materials and manufactured under recognized quality control

programs.

Instrumentation should

be installed on skid modules whenever possible, including all necessary

connections and wiring to junction boxes.

Instruments should be

pre-calibrated and function tested in the Vendor’s shop prior to export

packing; for PLC-controlled units, Factory Acceptance Testing must be

conducted, with the option for the Purchaser to witness at their own cost.

Preferably, PLCs should

be used in Vendor packages involving sequence and process control,

communicating with DCS and ESD systems via specified protocols.

Vendor-provided drawings

must accurately depict field instrumentation installation details, including a

Bill of Material, with each drawing representing typical installation details

for multiple tagged instruments.

All tube fittings must

be 316SS Swagelok or equivalent, with other bulk materials accurately described

in terms of material, size, pressure, and temperature ratings.

Flow and pressure

transmitters should be line-mounted whenever possible to minimize errors, but

accessibility must be ensured.

Instruments in vapor or

gas service should be mounted above the sensing point, while those in liquid

service should be mounted below; exceptions apply for pressure gauges.

Canopies must not be

provided for local control panels; sun shades must be provided for Analyzers

and RTU Panels.

When indoors, all vent

ports of instruments and regulators using instrument gas must be vented outside

the building.

Instruments, associated

components, and connections must be installed according to approved

installation drawings.

Local control pneumatic instruments should generally have output signals of 3 to 15 psi; electro-pneumatic devices should receive 4-20mA signals from the PLC system.

Instrumentation and

control systems should be designed for simplicity, reliability, and minimal

maintenance.

Field-mounted instrument

housings and exposed parts must be weatherproof and explosion-proof where

necessary.

All proposed plastic

components, along with toxicity and fire hazard details, must be specified in

the Vendor’s quotation.

The project piping

specification must determine process connection sizes, types, and ratings for

various instruments.

Special attention must

be given to material selection for instruments when dealing with highly

corrosive fluids or sour service.

All instrumentation and

control systems should be designed to operate in a fail-safe mode.

Instruments provided

with packaged equipment must be identified on mechanical flow sheets or

P&IDs and consistent with project requirements.

Instruments and components must be carefully selected to suit internal fluid conditions and environmental factors.

Packaged supplies must ensure instruments or their connections do not extend beyond the skid limits.

Instrument parts must withstand the corrosive properties of the process fluid they are exposed to.

Seals and purges should be employed as needed to guarantee reliable instrument performance.

0 Comments