GAS METERING SYSTEM

Flow measurement is required for various operational and fiscal purposes in various hydrocarbon processing facilities. Accurate measurement of flow is paramount as this flow reading is then used for the purpose of billing or flow allocations in case of mixed hydrocarbon flow from different reservoirs. An error of 0.1% in the flow measurement can impact significant change in flow allocations or it can impact the millions of dollars in case of fiscal applications. Due to the stated reasons; accurate measurement of flow is deemed essential but unfortunately, this flow measurement is not that pretty simple. There are underlying standards that have been developed by the subject matter experts and are being used by the manufacturers and end users for flow measurement, however, the uncertainty is still there. This subject is evolving as per the technological advancement and lessons learned from the experience of industrial application

KEY COMPONENT OF A TYPICAL GAS METERING SYSTEM

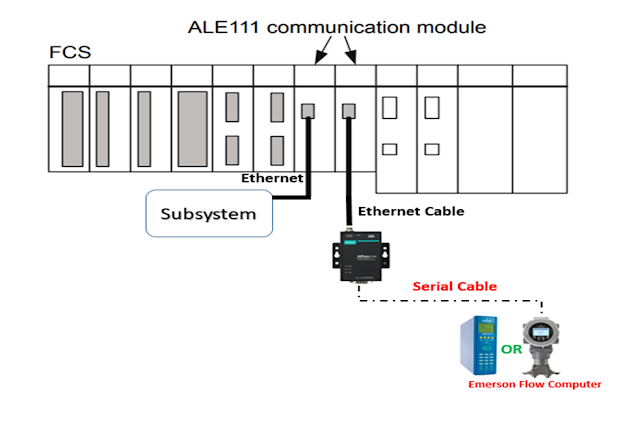

1. Flow Computers, Emerson’s Floboss S600 / S600+

2. C6+ Gas Chromatographs Manufacturer: Daniel

3. Ametek 3050 OLV Moisture Analyzers

4. Chart Records for each Metering Leg

5. Senior Orifice and Metering Transmitters

1) Flow Computer

(Floboss S600 & Floboss S600+)

- Uses AGA3 standard for orifice-based flow calculations

- Uses AGA8 standard for calculating compressibility

- Base conditions: 60 degree Fahrenheit and 14.65Psia

2. Gas Chromatographs

(Analyzer Model 500 series + 2350A Controller)

- Uses the GPA2172 standard for calculating the physical properties of natural gas components including density and heating value

- Provides heating value to flow computer for use in energy calculations against volume delivered( 02 Each C6+ gas chromatographs.

3. Moisture Analyzers

- Measure moisture contents in sales gas. It feeds moisture value to respective GCs.

* 3050 SLR is also installed

4. Barton Chart Recorder

- Manual flow recording is done through barton charts on daily basis (8am to 8am)

- They are referred to as conditions when there is some anomaly with the electronic flow measurement

5. Senior Orifice and Metering Transmitters

(Transmitter Make: Rosemount)

- DP calculations are done for flow measurement against Daniel's senior orifice

- Metering Transmitters include 02 DP transmitters (for low and high flow), 01 temperature transmitter and 01 static pressure transmitter per metering leg.(Make: Rosemount).

Each metering skid consists of 03 legs and total number of transmitters sums up to 12.

0 Comments